Ukwaleka kweTa-C ekubumbeni

Ukusetyenziswa kwe-ta-C coating ekubumbeni:

I-tetrahedral amorphous carbon (ta-C) yinto eguquguqukayo eneempawu ezikhethekileyo ezenza ukuba ifaneleke kakhulu kwiindlela ezahlukeneyo zokusetyenziswa ekubumbeni. Ubulukhuni bayo obungaqhelekanga, ukumelana nokuguguleka, i-coefficient ephantsi yokungqubana, kunye nokungangeni kweekhemikhali kunceda ekuphuculeni ukusebenza, ukuqina, kunye nokuthembeka kwee-molds kunye neemveliso ezibunjiweyo.

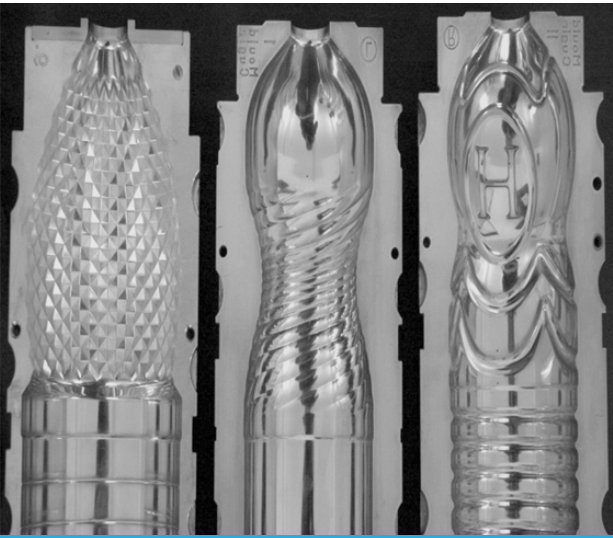

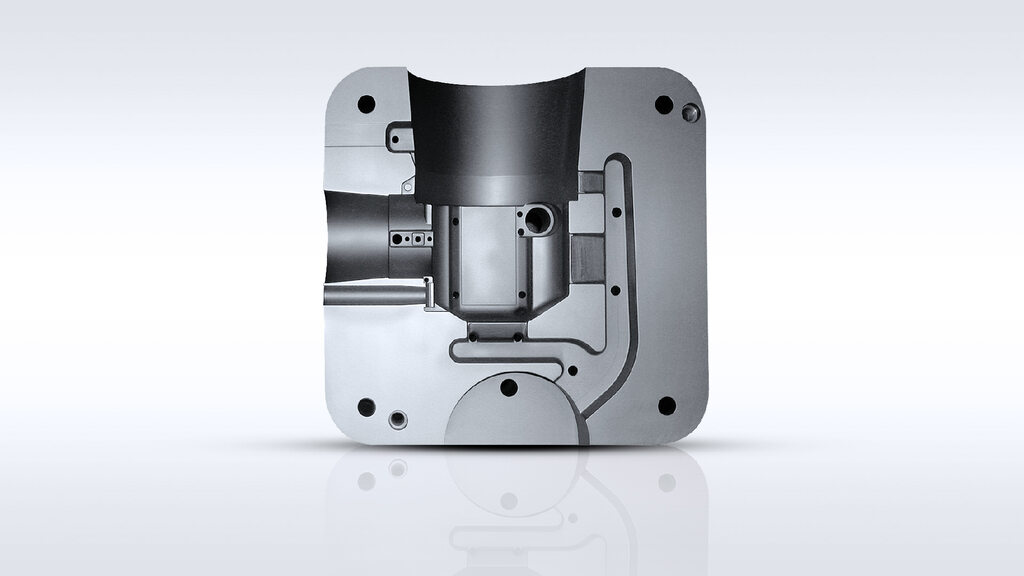

1. Ukubumba ngenaliti: Iingubo ze-ta-C zifakwa kwimiqolo ye-injection mold ukuphucula ukumelana nokuguguleka kunye nokunciphisa ukungqubana ngexesha lenkqubo yokumba kunye nokukhupha. Oku kwandisa ubomi be-molds kwaye kuphucula umgangatho womphezulu weendawo ezibunjiweyo.

2. Ukugalela ngesinyithi: Iingubo ze-ta-C zisetyenziswa kwiidayi zokugalela ngesinyithi ukukhusela ekugugulekeni nasekungcoleni okubangelwa kukuhamba kwesinyithi esinyibilikisiweyo. Oku kwandisa ukuqina kweedayi kwaye kunciphisa iziphene zokugalela ngesinyithi.

3. Ukubumba i-extrusion: Iingubo ze-ta-C zifakwa kwii-extrusion dies ukunciphisa ukungqubana kunye nokuguga ngexesha lenkqubo ye-extrusion. Oku kuphucula umphezulu weemveliso ezikhutshiweyo kwaye kunciphisa ukunamathela kwezinto kwii-dies.

4. Ukubumba irabha: Iingubo ze-ta-C zisetyenziswa kwiibumba zerabha ukuphucula ukukhululwa nokuthintela ukunamathela kweendawo zerabha kumphezulu wokubumba. Oku kuqinisekisa ukuguguleka okuthambileyo nokunciphisa iziphene.

5. Ukubumba iglasi: Iingubo ze-ta-C zifakwa kwiingubo zeglasi ukukhusela ekugugulekeni nasekukrweleni ngexesha lenkqubo yokubumba. Oku kwandisa ubomi bengubo kwaye kuphucula umgangatho womphezulu weemveliso zeglasi.

Lilonke, iteknoloji yokugquma ye-ta-C idlala indima ebalulekileyo ekuphuculeni iinkqubo zokubumba, inegalelo ekuphuculeni umgangatho wemveliso, ukunciphisa iindleko zemveliso, kunye nobomi obude bokubumba.